Water Recycling & Treatment

Efficiency and Sustainability in Every Drop

Clean water in every drop - for healthier plants and a healthier planet

Save water, fertilizer, and money by recirculating your irrigation solution. INTA offers several customized configurations to match your needs, from mixing control before the fertigation unit, to integration within the recycling bag or directly in the equipment tank. Our systems can also blend water from different sources, ensuring the irrigation solution remains balanced and in optimal condition for reuse.

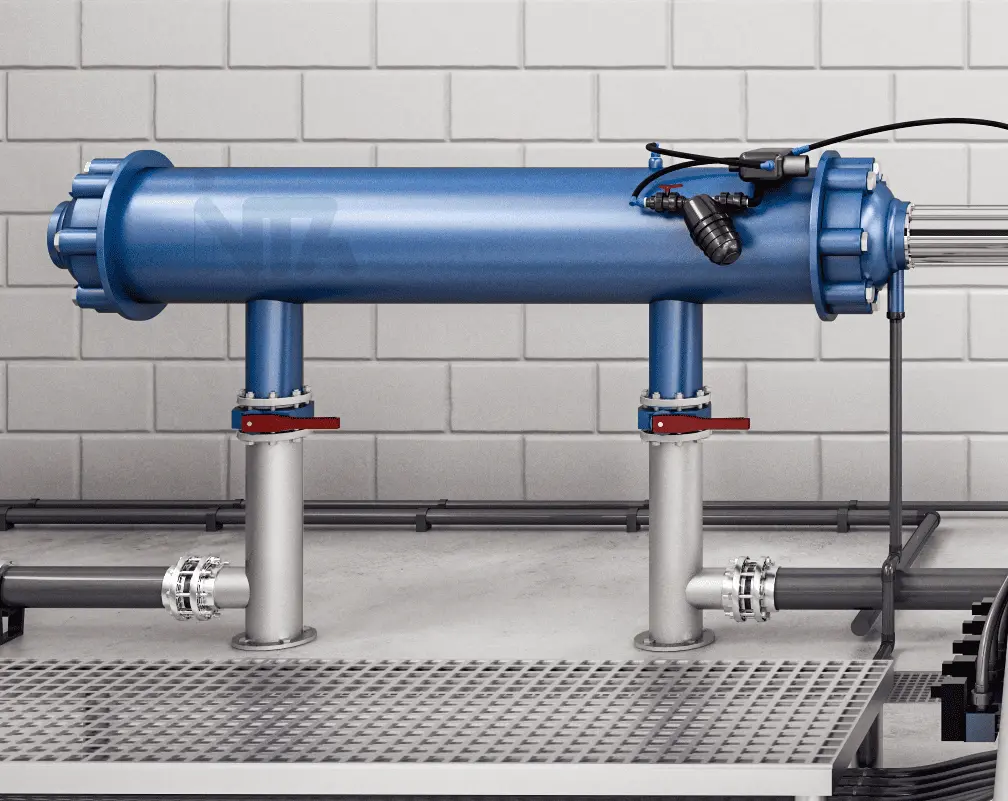

To safely reuse irrigation water, we recommend incorporating a disinfection system. Our UV radiation equipment provides a simple, effective method to keep the irrigation solution free from pathogens, protecting your crops from diseases, fungi, and bacteria while maintaining water quality.

For specific applications, we can also integrate alternative biocidal systems, offering a complete, flexible approach to water treatment that supports both efficiency and sustainability.

Highlighted functions

Significant savings in water and fertilizers

Up to 30% (or more) water reuse depending on the crop, directly reducing production costs while maintaining consistent plant nutrition

Designed for sustainable agriculture

Helps growers meet environmental goals and industry regulations by reducing wastewater and preventing nutrient runoff into the environment

Flexible integration with any farm setup

Multiple configuration options: before the fertigation unit, in a central mixing tank, or inside a recycling bag. Adaptable to each installation

Safe reuse through high-efficiency disinfection

UV radiation technology ensures irrigation water is free of pathogens such as bacteria, fungi, and viruses, protecting plant health and yield

Advanced treatment technology when required

Compatibility with alternative biocidal systems (ozone, heat, chemical injection) for projects with specialized needs or stricter sanitation standards

Total quality control of irrigation water

Continuous monitoring of EC, pH, and sanitation levels guarantees that recycled water remains in optimal condition at all times

Full automation with EVO & Sysinta

Irrigation and disinfection are controlled intelligently and remotely, ensuring maximum efficiency with minimal labor. (Añadir un botón de About EVO, Advanced climate control y Sysinta, que te lleve a su pagina)

Highlighted functions

Significant savings in water and fertilizers

Up to 30% (or more) water reuse depending on the crop, directly reducing production costs while maintaining consistent plant nutrition

Designed for sustainable agriculture

Helps growers meet environmental goals and industry regulations by reducing wastewater and preventing nutrient runoff into the environment

Flexible integration with any farm setup

Multiple configuration options: before the fertigation unit, in a central mixing tank, or inside a recycling bag. Adaptable to each installation

Safe reuse through high-efficiency disinfection

UV radiation technology ensures irrigation water is free of pathogens such as bacteria, fungi, and viruses, protecting plant health and yield

Advanced treatment technology when required

Compatibility with alternative biocidal systems (ozone, heat, chemical injection) for projects with specialized needs or stricter sanitation standards

Total quality control of irrigation water

Continuous monitoring of EC, pH, and sanitation levels guarantees that recycled water remains in optimal condition at all times

Full automation with EVO & Sysinta

Irrigation and disinfection are controlled intelligently and remotely, ensuring maximum efficiency with minimal labor. (Añadir un botón de About EVO, Advanced climate control y Sysinta, que te lleve a su pagina)

Other products you may be interested in

Contact with us

Any additional information, question or remarks, please feel free to call us +34 968 493 116.

Or leave a message

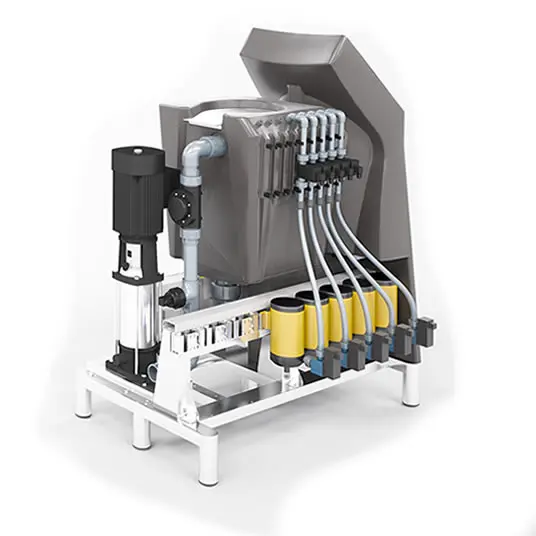

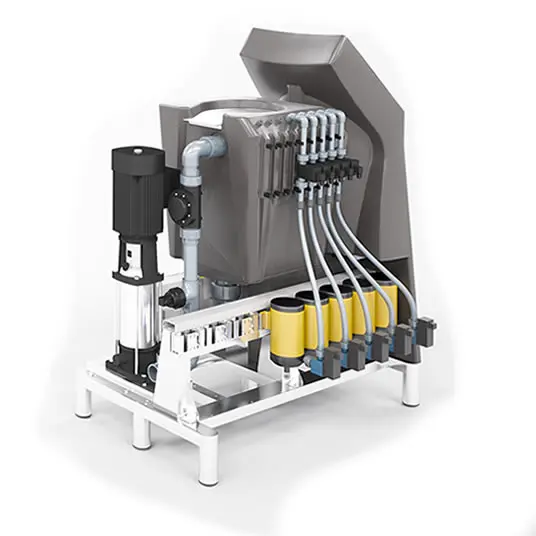

CDN: Fertigation

Hydraulic design confirmed over 25 years of experience

Fertilizer mixing tank

Specially designed to produce a homogeneous and quick mixing of the different fertilizers.

Magnetic Pumps

They drive the fertilizer solution from each fertilizer tank to the mixing tank.

3-way dosage electrovalves

They regulate the dosage of the different fertilizers in terms of the proportions established for each tank. As it is 3-way, it permits a return circuit to be maintained with the fertilizer tanks, considerably improving the functioning and precision of the dosage.

Fertilizer flowmeters

High frequency flowmeters which consequently measure the fertilizer dosage volume of each tank with greater precision. They register the consumption in real time, and allow us to automatically adjust the dosage.

pH probe

Robust and reliable pH probe, working in line and with pressure. Essential for a correct pH control via the acid dosage.

EC probe

Measures conductivity, with automatic temperature compensation. Robust and reliable, heavy duty.

Main pump

Multi-stage vertical pump which drives the fertilizer solution. Made in AISI 316 steel. Adjusts model adjusted according to flows and irrigation pressure.

Fertigation Controller

Controls all the described elements, as well as other elements of the irrigation installation.

INTA CROP TECHNOLOGY, S.L. HA SIDO BENEFICIARIO DEL PROGRAMA DE AYUDAS PARA LA PARTICIPACIÓN EN LA MISIÓN COMERCIAL INVERSA A PERÚ, MÉXICO Y EGIPTO 2024, COFINANCIADO POR EL FONDO EUROPEO DE DESARROLLO REGIONAL. EXPEDIENTE: 2024.05.MI16.000090